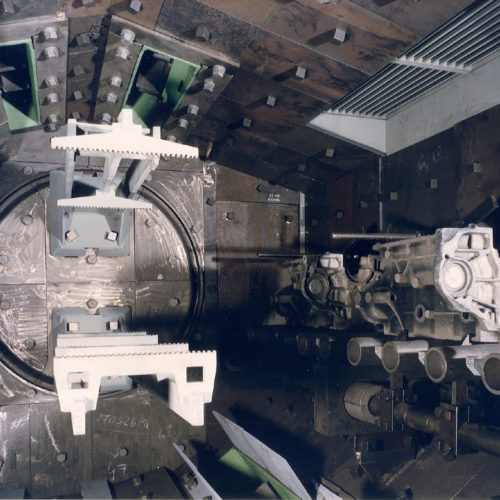

Pangborn Gripper Blast Machines offer high volume production and minimal or no-tooling changes while processing a large volume of different size and configuration engine blocks, crank cases, gear housings, manifolds, heads, transmission cases, and other vehicle parts. Cleaning deep cavities in a cast iron or light metal casting quickly and cost effectively has always presented a challenge to companies in the automotive and off-highway vehicle industries. The size and weight of engine block and head components, as well as the presence of blind passages and internal cavities, make cleaning much more complicated.

When high volume production, flexibility, efficiency, minimal down-time, and cost-effective technical solutions are required, the fully automatic Pangborn Gripper Blast Machines are the preferred choice.

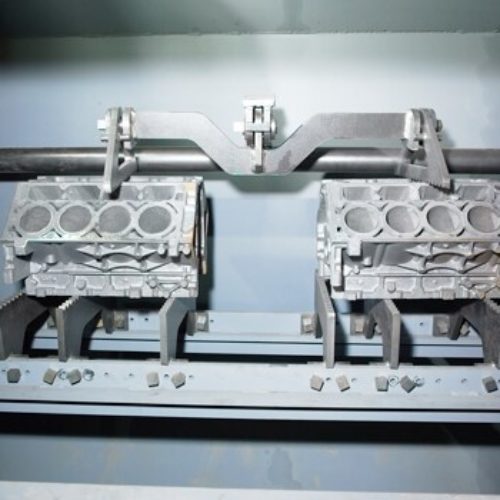

The Gripper Blast Machines clean engine blocks in varying sizes – from 4 cylinders to V10 diesels. The hydraulic load/unload mechanism is equipped with positive stop location to accurately position parts in the gripper. Depending on work piece configuration, the gripper rotation can be programmed to achieve the desired coverage and an improved cleaning efficiency on specific areas.

The machine is equipped with a special system designed to rotate work pieces on one or two axes to evacuate residual abrasives after discharging. Advanced solutions for work piece handling are also available. All sides of the work piece are exposed to blasting, and the gripper jaw rotation allows for proper abrasive drainage.

Gripper blast machines from Pangborn are tailored to each customer’s unique requirements and specifications.

P-41 Alloy and Steel Construction for:

Genesis Wheel Technology:

High Efficiency Separator:

Electronics Package:

Pangborn Gripper Blast Machines are the perfect surface cleaning machines for engine blocks and heads, grey iron, and aluminum.

Customers of Pangborn’s surface preparation machines enjoy high quality, cost effective, operationally efficient shot blasting machines.

Features and options may vary by model and/or configuration. Speak with your Pangborn representative to learn more.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2025 Pangborn. All Rights Reserved. Privacy Policy