The blast wheel is an important variable that influences and determines the overall efficiency and operating cost of a blast cleaning system. Quality blast wheels must be durable, easy to maintain, and meet all performance standards.

Pangborn offers the most versatile line of blast wheels in the industry including from 13″ (330.2 mm) to 26.5″ (673.1 mm) diameters, wheels with various speeds, vane, impeller, and impeller case designs that are used to handle the most challenging blast application.

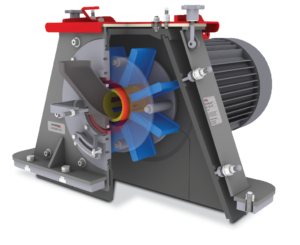

Developed and supported by more than 100 years of blasting and cleaning experience, Pangborn’s Genesis family of blast wheels are revolutionary new wheels that offer significant savings and competitive advantages. The new Genesis technology takes ease of blast wheel maintenance to a whole new level—and drives savings straight to the bottom line.

Regardless of the harsh conditions that exist within foundries, the high output requirements of automotive industries, or the exacting tolerances of peening specifications, Genesis Wheels are proving that they are not only one of the most technologically advanced wheels on the market, they are also the most versatile.

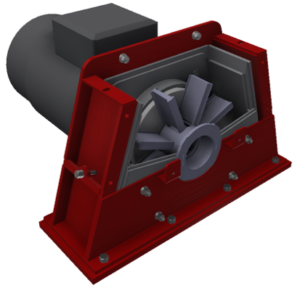

The Acu-Strike wheel is a single sided high efficiency unit with minimal energy consumption and low running costs. The blast wheel is designed for maximum performance in all descaling, finishing, foundry and forge applications.

The wheels are manufactured, assembled and tested in our UK facility.

The canted vanes are produced with Pangborn’s P-41 alloy, processed by investment casting and fully heat treated. The casting process ensures repeatable tolerances for assembly fit and weight. The consistency and quality of the vanes deliver uniform service wear across the entire set of vanes and extends the in-service life of the electrical motors.

The Acu-Strike Canted wheel design has the following advantages:

Our V+S style wheels are designed to accommodate a quick exchange of the complete impeller wheel turbine for repair or replacement. Held in place by three position bolts, the blast wheel is easily removed from the blast machine by using a crane or lifting hoist.

Pangborn offers a variety of specialty wheels for unique blast environments and we provide parts and service for older wheel models and non-Pangborn blast wheels.

Pangborn, Genesis, Acu-Strike, RIM-LOC, and RotoBlast are all registered trademarks of Pangborn.

Learn more about Pangborn’s blast cleaning and shot peening equipment solutions.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2024 Pangborn. All Rights Reserved. Privacy Policy