Shot blasting is a surface preparation process used to remove debris, irregularities and other contaminants from concrete, metal, and other industrial surfaces.

1904

Pangborn develops the process known as sandblasting

Pangborn pioneers the use of metal abrasives to replace sand

1920

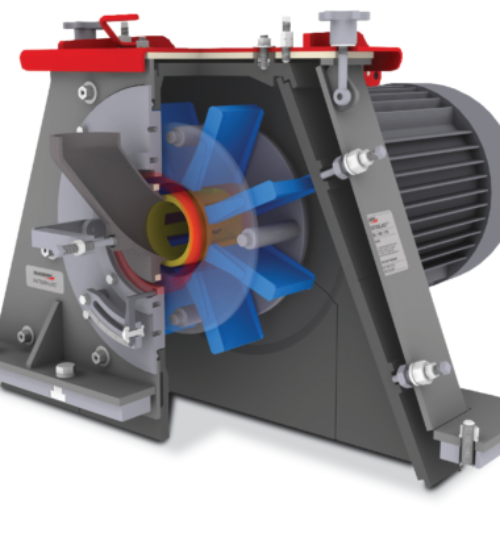

A wheelblast machine uses an electric motor (centrifugal wheel) to rotate a turbine wheel, which then rotates at high speed and generates a stream of abrasive particles (abrasive material). These large amounts of accelerated abrasives are used where big parts, large areas of parts, or heavy duty parts need to be derusted, scaled, deburred, sanded, or cleaned in some form or another. The shot media, including steel shot, cut wire, and nuts, is loaded into a hopper that then feeds the blast wheel. The media can “blast” off almost anything, from rust to epoxy.

While shot blasting is done to clean surfaces, it’s also used to prepare them. Shot blasting a surface before painting it or coating it is an effective and efficient way to literally smooth out those processes.

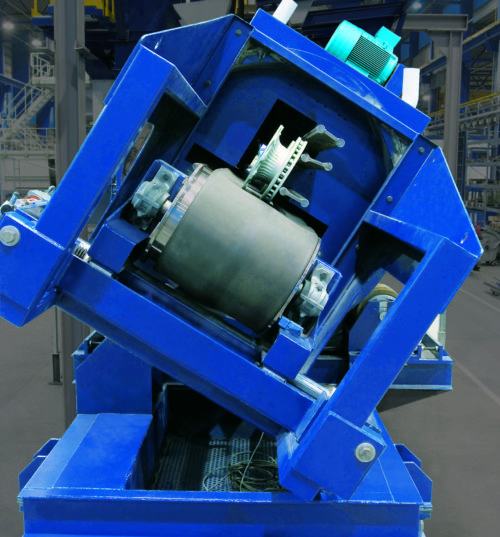

The method of transport of the components to be blast-cleaned will determine the type of machine used: from simple table machines to automatic manipulator machines used by full series automotive manufacturers, to roller conveyors, stripping systems and more.

Check out our line of ShotBlasting Machines and solutions!

Overview video of Pangborn's BE Separator with Abrasive Curtain Control System.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2025 Pangborn. All Rights Reserved. Privacy Policy