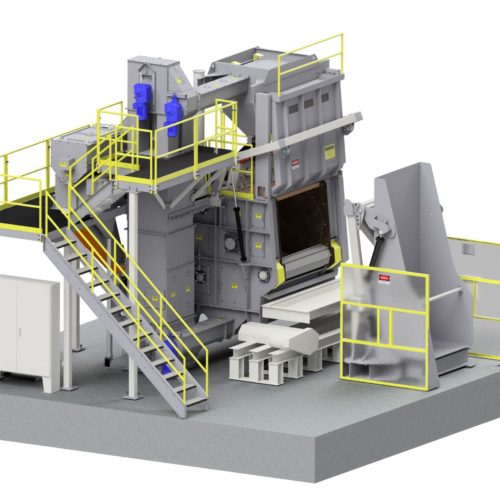

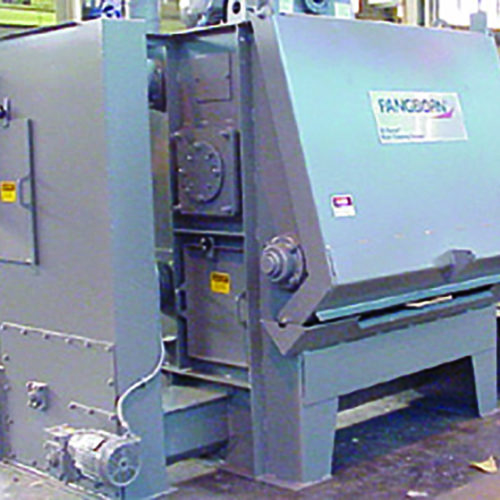

The heavy-duty Pangborn Barrel Blast Machine is exclusively designed to thoroughly clean all types of castings, forgings, weldments, heat-treated work, and stampings. Our barrel blast machines are designed to process a variety of work pieces that can be tumbled, and the endless conveyor belt and lateral round place creates a trough in which work pieces are treated.

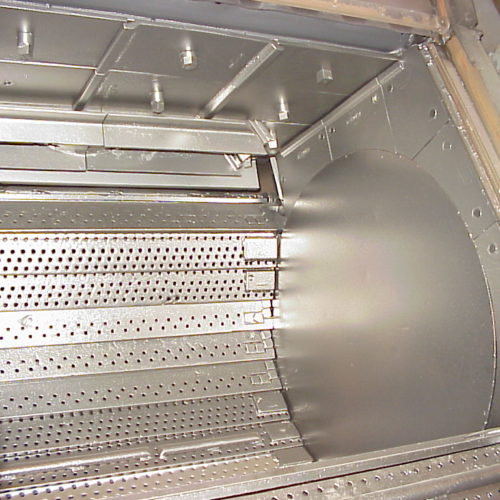

The loading and unloading process is specifically geared to the work piece and workspace requirements. The optimum adjustment of the blast capacity is specified to the required blasting result. The tumbling action provided by the rubber or metal conveyor ensures that all surfaces of the work piece are cleaned in a single batch.

Pangborn offers a variety of barrel sizes depending on the size of the work pieces being blasted. Most often, larger machines are used for high output cleaning on medium sized castings, forgings, or fabricated work pieces. Barrel Blast Machines allow for a high volume of work pieces to be processed in a small working area.

Highly configurable, these machines can be delivered with a rubber or metal conveyor, vibratory conveyor, magnetic separator, hydraulic loader, unloading conveyor, and dust collector.

P-41 Alloy and Steel Construction for:

Genesis Wheel Technology:

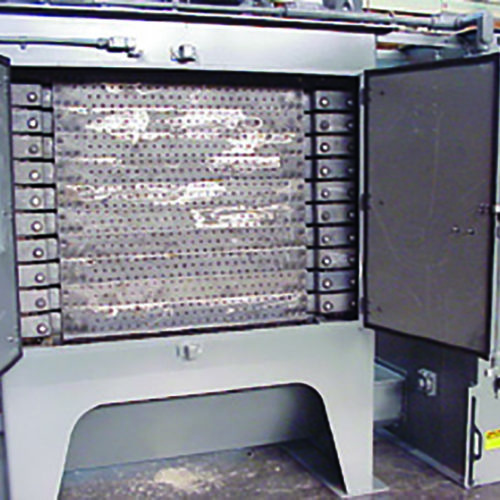

High Efficiency Separator:

Electronics Package:

Pangborn Barrel Blast Machines tumbling action, provided by the endless rubber or metal internal conveyor, ensures all surfaces of the work piece are cleaned in one loading.

Customers of Pangborn’s surface preparation machines enjoy high quality, cost effective, operationally efficient shot blasting machines.

Features and options may vary by model and/or configuration. Speak with your Pangborn representative to learn more.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2025 Pangborn. All Rights Reserved. Privacy Policy