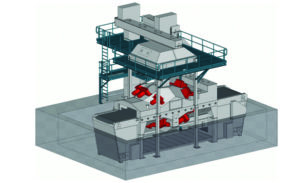

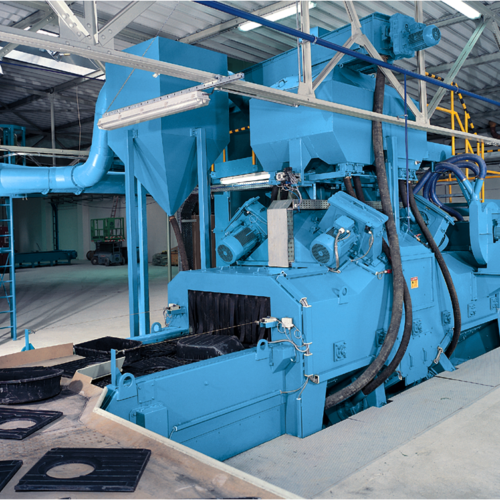

Pangborn Wire Mesh Belt Blast Machines are a versatile option designed to blast clean work pieces on two sides in one pass through. Whether it’s for heavy duty foundry applications or thin and fragile castings, our Wire Belt Mesh Blast Machines can handle any job.

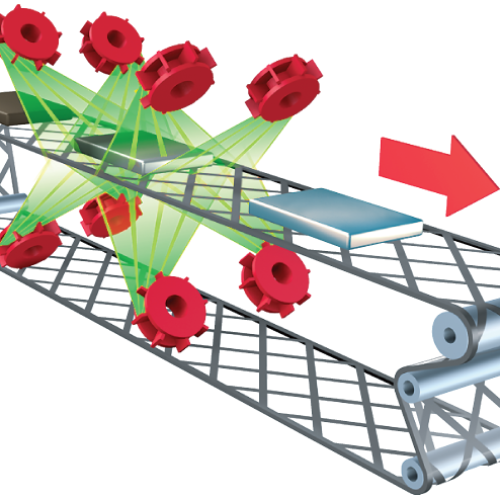

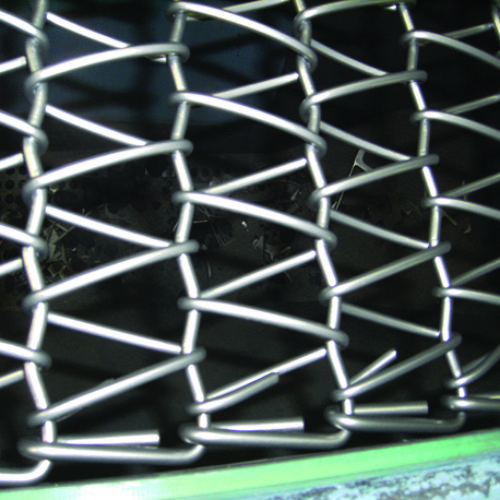

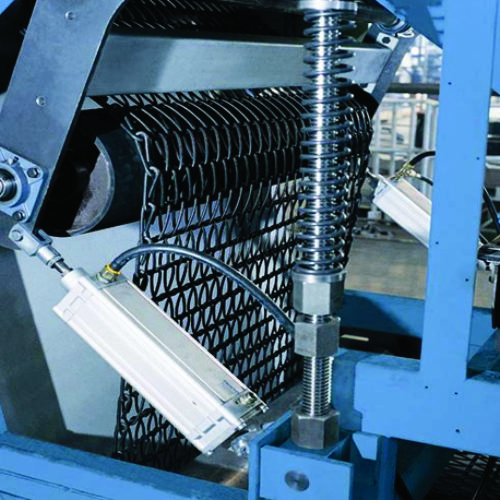

The blast chamber is bombarded with abrasive stemming from wheels situated both above and below the work as it passes through the chamber. The result is complete blast coverage with superior one pass continuous cleaning without damaging work pieces.

Pangborn Wire Mesh Belt blast machines, specifically engineered for heavy duty applications in foundry, are equipped with a lower scalping deck and designed in accordance with heavy duty usage philosophy.

Our Wire Mesh Belt blast machines can blast work pieces that require a smooth or shockless pass through, such as flat, thin-walled, and fragile iron or aluminum alloy castings. Due to the position of blast wheels, bending of thin-walled work pieces and tilting of small light parts is avoided. Our machines are also designed to handle the high temperatures of work pieces that have been heat treated.

Pangborn Wire Mesh Belt blast machines provide high-volume, cost effective performance for deburring, cleaning, descaling, deflashing, and etching.

P-41 Alloy and Steel Construction for:

Genesis Wheel Technology:

High Efficiency Separator:

Electronics Package:

Pangborn Wire Mesh Belt Blast Machines can blast heavy duty small to medium sized work pieces as well as fragile castings. The blast chamber is bombarded with abrasive stemming from wheels situated above and below the work for maximum coverage.

Customers of Pangborn’s surface preparation machines enjoy high quality, cost effective, operationally efficient shot blasting machines.

Features and options may vary by model and/or configuration. Speak with your Pangborn representative to learn more.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2025 Pangborn. All Rights Reserved. Privacy Policy