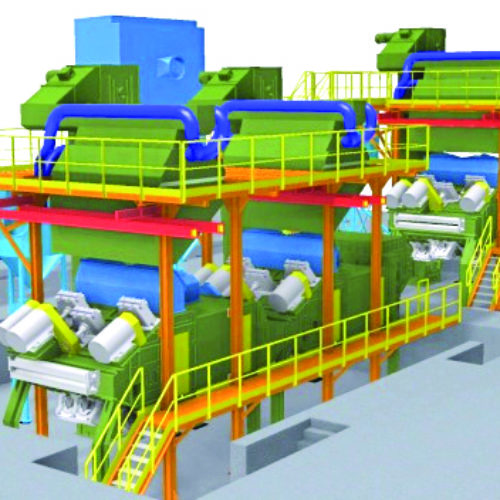

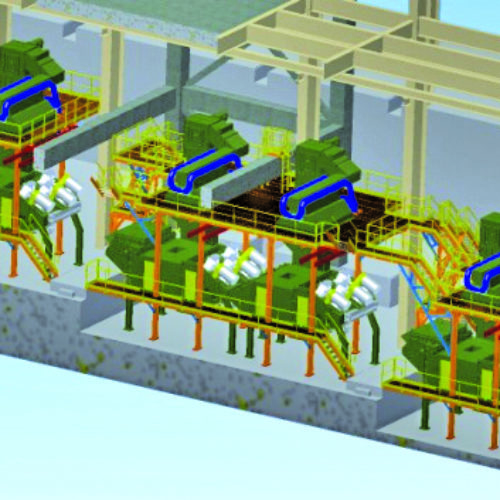

The machines treat different strip widths (ranging from 0’2″ to 2’7″ (50 to 800 mm) for the narrow strips and from 2’7″ to 6’11” (800 to 2100 mm) for the large strips), horizontally or vertically positioned.

The modular blasting cabinets are conveniently arranged and equipped with up to twenty-four (24) 125HP (90 kW) wheels to achieve the required production rate. Automatic blast stream inclination and automatic abrasive flow adjustment devices are also available.

To optimize the stream position according to the strip width, particularly for narrow strips, an automatic blast cabinet orientation system is available.

P-41 Alloy and Steel Construction for:

Genesis Wheel Technology:

High Efficiency Separator:

Electronics Package:

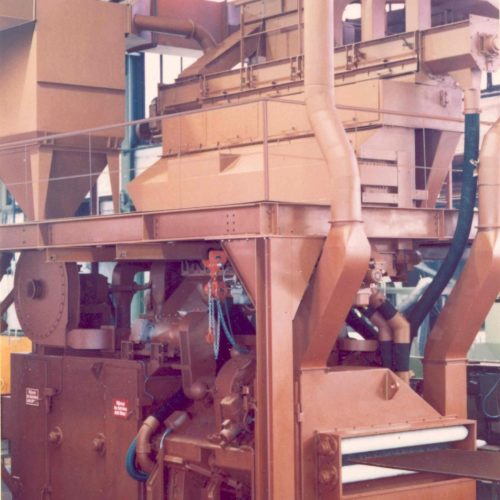

Pangborn Steel Strip Descaler Machines are designed to blast clean steel strips (carbon, alloy, or stainless steel) on a continuous passage at a specified speed.

Customers of Pangborn’s surface preparation machines enjoy high quality, cost effective, operationally efficient shot blasting machines.

Features and options may vary by model and/or configuration. Speak with your Pangborn representative to learn more.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2025 Pangborn. All Rights Reserved. Privacy Policy