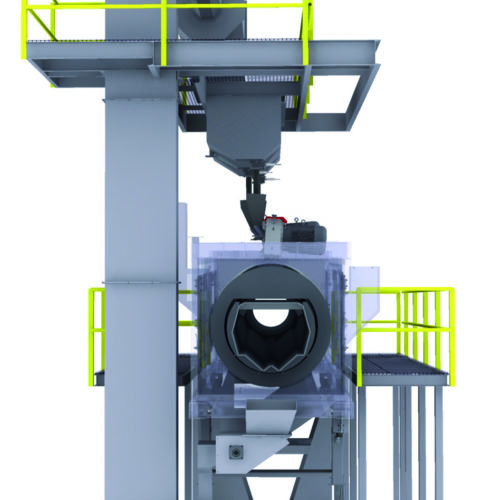

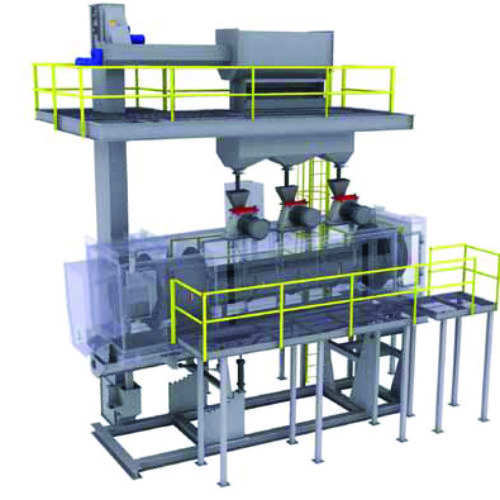

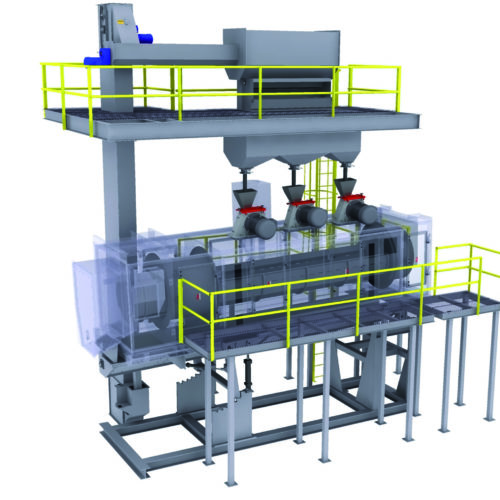

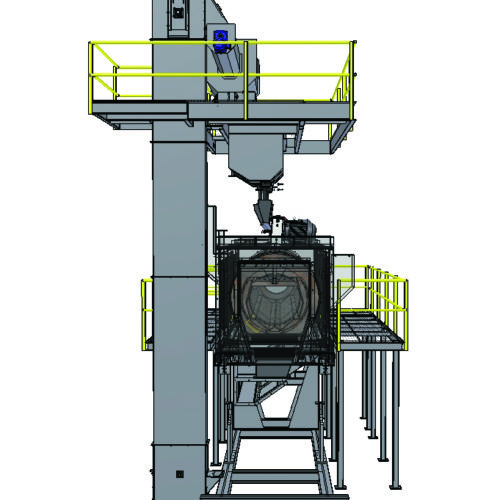

Blast cleaning cycles are fully adjustable with programs to modify process parameters (including abrasive flow and passage speed) depending on the needs of the line or the work pieces. Pangborn offers a variety of barrel sizes to accommodate a wide range of work piece sizes being blasted. The Continuous Barrel Machine can blast up to 37 tons of per hour. Several loading and unloading solutions are available.

P-41 Alloy and Steel Construction for:

Genesis Wheel Technology:

High Efficiency Separator:

Electronics Package:

The Pangborn Continuous Barrel Machine is an ideal solution for high rate situations demanding an efficient production line without an operator.

Customers of Pangborn’s surface preparation machines enjoy high quality, cost effective, operationally efficient shot blasting machines.

Features and options may vary by model and/or configuration. Speak with your Pangborn representative to learn more.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2025 Pangborn. All Rights Reserved. Privacy Policy