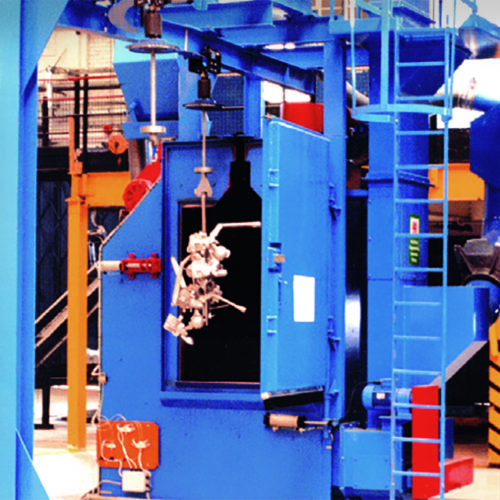

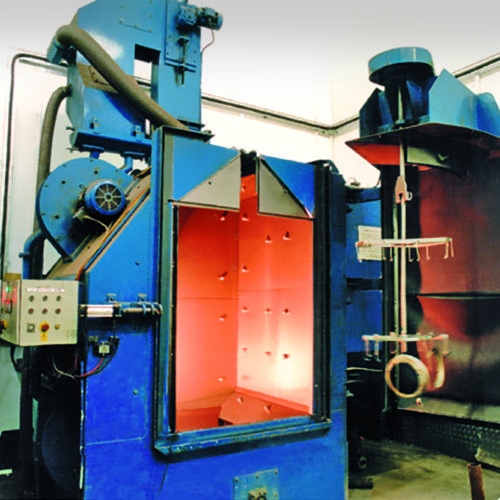

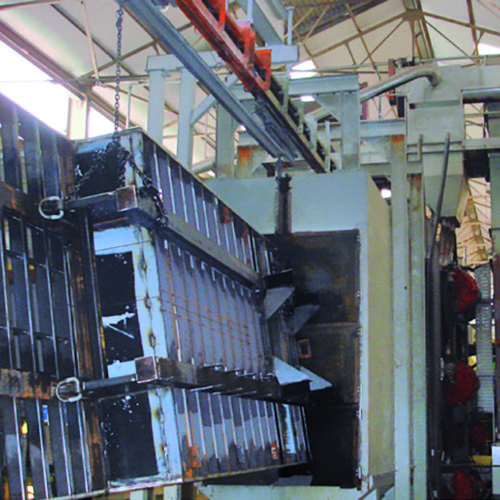

Pangborn’s Hanger Hook Blast Machines are the ideal all-purpose blasting machines. They are designed to handle mixed loads of medium and large components as well as loads with fragile or irregularly shaped work pieces. They are specifically designed to thoroughly clean work that cannot touch. There is no movement between the work and no part-on-part contact ensuring complete blast coverage without tumbling damage or tangling parts.

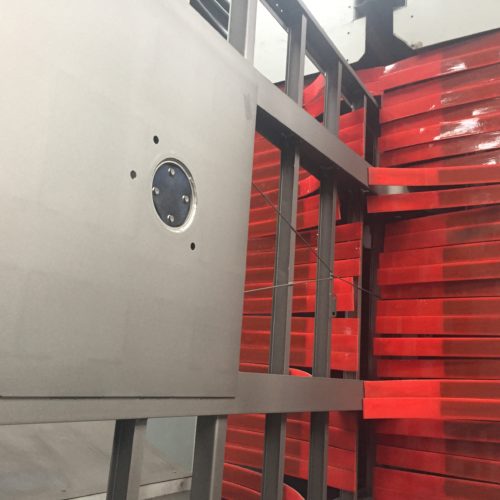

While a variety of sizes and configurations are available, a standard hook blasting machine has a generous work cylinder. Standard models come with three blast wheels, and more can be added as necessary for even greater coverage.

A Hanger Hook machine ensures better abrasive coverage by rotating or spinning the hook under the abrasive wheel streams while stopping in multiple positions. The ergonomics of work piece loading is improved with lifting hooks and optional self-powered trolleys.

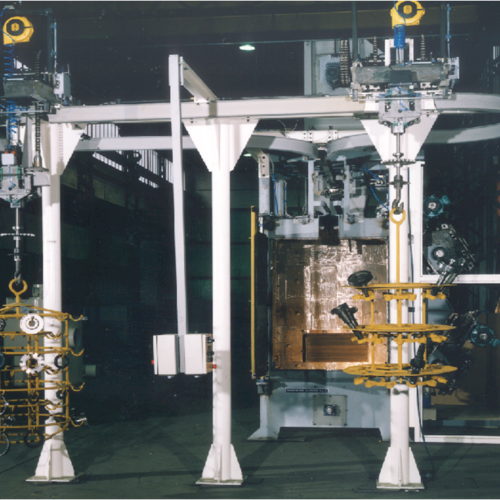

For automatic operation sequences or integration of the shot blast machine into a continuous production line, loading and unloading can be performed without operator assistance. In this case, an industrial robot is used which also serves to link the individual manufacturing sequences.

Versatile, economical, and reliable, the Hanger Hook Blast Machine is designed as an all-purpose blast cleaning unit.

P-41 Alloy and Steel Construction for:

Genesis Wheel Technology:

High Efficiency Separator:

Electronics Package:

Pangborn Hanger Hook Blast Machines are versatile blast cleaning machines for mixed loads of medium and large work pieces that frequently include fragile or irregularly shaped work pieces.

Customers of Pangborn’s surface preparation machines enjoy high quality, cost effective, operationally efficient shot blasting machines.

Features and options may vary by model and/or configuration. Speak with your Pangborn representative to learn more.

Pangborn provides superior shot blasting equipment and surface preparation solutions. Our sales, engineering, and service teams design best-in-class solutions, parts, and service that help our customers drive operational excellence, realize improved total cost of ownership, and increased profitability.

Pangborn and Genesis are registered trademarks of Pangborn.

© 2025 Pangborn. All Rights Reserved. Privacy Policy